Weldless Tubes

How did weldless tubes come about?

Born from the idea of theMannessman brothers, who in 1886 obtained a worldwide patent for a two-roller cross-piercing machine (rotary), weldless tubes preceded welded tubes and quickly found wide use in industry. Later, the production process was improved by the addition of new machinery, such as the automatic tube rolling machine made in 1903 by the Swiss company Ritteriefel, and later various types of extrusion and rolling machines and pipe-pushing machines.

The Uses and Applications of weldless tubes

Before the production technology of welded tubes reached its maturity (which was later than that of weldless tubes), the uses were different, as welded tubes were typically suitable for low-cost applications and under low pressures. Later, through progressive improvements, the two types of tubes have become almost equivalent, except for some technical specifications regarding thicknesses and diameter. Weldless tubes are still preferred, as they are considered more reliable for high operating pressures above 250 bar.

AlTA Spa’s weldless tubes

Starting from the basic product on the market, the superiority of ALTA’s tubes is due to their internal processing, which ALTA manufactures in house with proprietary and exclusive machines and technologies (a finish that is as suitable for welded as for weldless tubes).

They are therefore particularly suitable for oil hydraulic cylinders (which are used in machine tools, robots, forklifts, elevators, cranes, agricultural machinery, automatic bulkheads, wind generators, etc.) and for oil hydraulic accumulators: in practically any assisted movement that requires power and force (hydraulic, in our case), with the most varied applications: from garbage compactors and gate openers, all the way to car and truck power steering, railroad transport, presses and bending machines.

Weldless tubes for oil hydraulic cylinders

Weldless tubes for cylinders produced by ALTA Spa with advanced mechanical features and manufactured with special steels.

SEE

Weldless Tubes for Accumulators

Weldless Tubes for Accumulators

Weldless tubes for accumulators produced by ALTA Spa: wide size range, specially-manufactured advanced mechanical features.

SEE

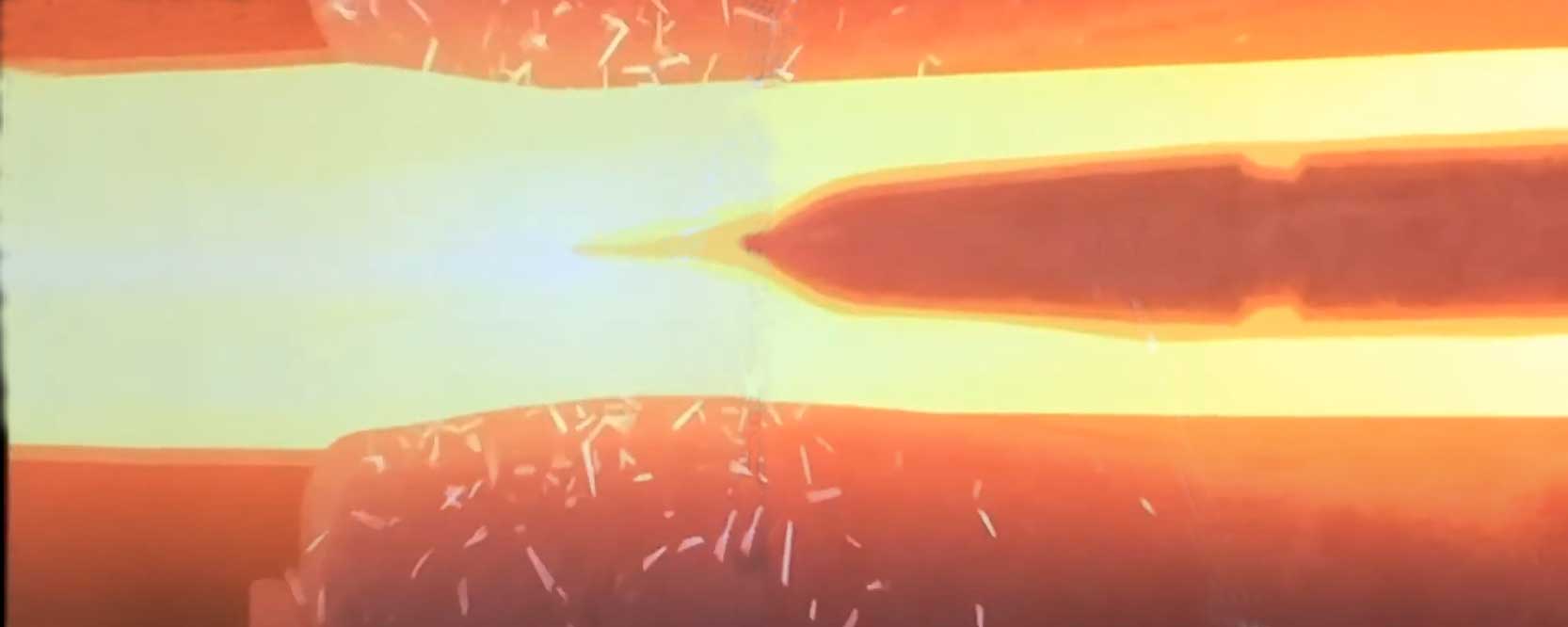

Tube drilling and the hot rolling process

The process begins with rebar drilling, the first product of the molten steel casting process. The rebar are heated to about 1100°C for maximum ductility, and hot-drilled (see video below) with an ogive tipped rod, which is pushed against the rotating rebar with great force. This combined pushing and rotating operation is followed by drilling, the result being that the round rod is stretched as it is being transformed into a tube. Now formed, but stil rough, this is called a “mother tube”. Steel mills are equipped with tools with which to produce two or three mother tubes, each in different sizes and progressively smaller diameters in accordance with the diversity of the dimensional range of production and sale. Processing continues by feeding one of the mother tubes into a hot reduction rolling mill, which by rotating and compressing the outer surface only, takes advantage of the residual ductility reduced by the decreased temperature, and improves the external surface and tolerances. The rolling mills are equipped with a number of cages in succession, which have the capacity to further reduce external size to that for which production was planned.

The materials

Weldless tubes are manufactured strictly with high-quality steels.

- E355 steelhas lower carbon content, and amounts of manganese and silicon are added, which provide a steady balance between mechanical properties and the rigidity needed to make a stem, while achieving resilience features of 27 Joules on average at -20°C*.

- E410 steel, an E355 with between 0.08% and 0.15% added vanadium. This is available for weldless tubes only. Its mechanical properties are superior to E355. One of its main features is “hot precipitation” – this means that if a weld intervened in an area of an E355 steel tube, its mechanical properties would drop to those of the heat with which it was produced. In the presence of vanadium, its molecule tends to concentrate in the welded zone, maintaining a high level of mechanical properties.

The difference between weldless and welded tubes

- Weldless tubes favor material continuity (precisely because they are produced whole), but welded tubes favor geometric precision (as they are made from sheet metal with precise and consistent thickness).

- Weldless tubesare capable of tolerating higher pressures .

- For weldless tubes, surface defects in the billet (the part protruding from the furnace) cannot be eliminated by the hot and cold rolling processes. In the wall reduction process (attaining the required diameters) defects can only be partially eliminated.

- Welded steel tubes come from hot rolled coils as raw material, and coil surface quality is easier to control than tube surface quality. Hot rolled coils have a high surface quality. Therefore, the surface quality of welded tubes is much higher than that of weldless tubes.