ALTA finishing

For over 50 years, ALTA has been the epitome of excellence for our choice of the finest materials and unique surface finish manufacturing.

For over 50 years, ALTA has been the epitome of excellence for our choice of the finest materials and unique surface finish manufacturing.

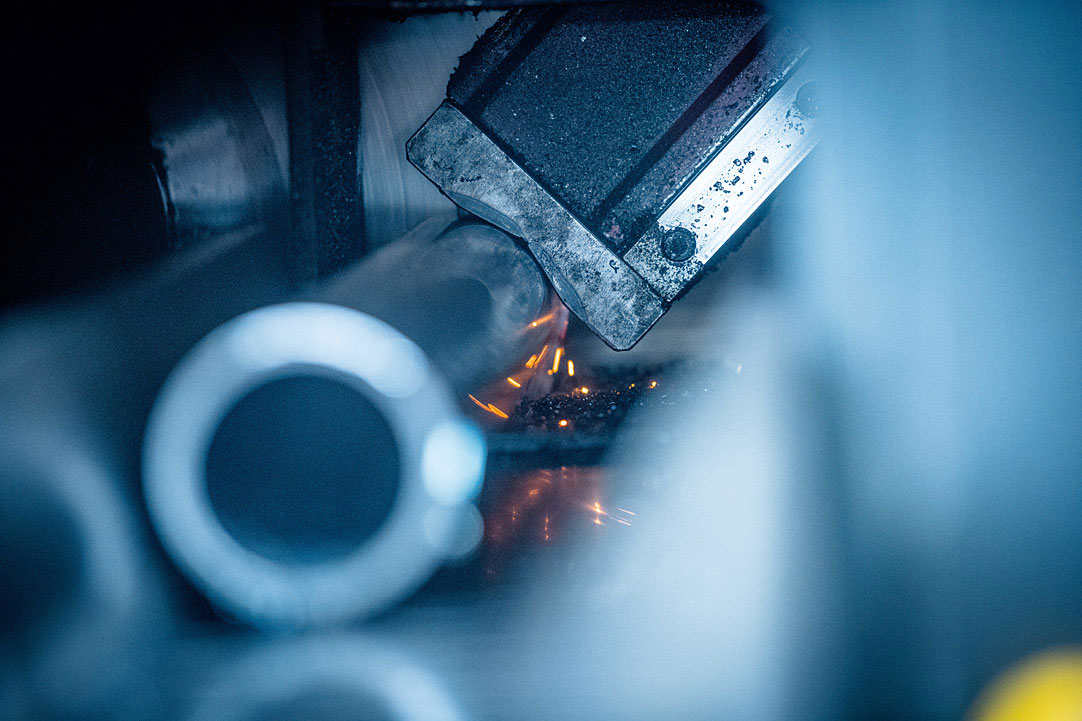

Through our internal finishing production process, we achieve an RA profile characterized by exclusively negative micro peaks, which generate small oil pockets that improve lubrification and improve seal life for a longer period, as well as creating an optimal bearing surface.

Our production process also performs better on internal straightness against the maximum tolerances allowed by the standards

and the profile bearing goes over 50% at 1 my depth.

Finally, ALTA has an automated patented system, which scans the tube surface after machining, and can detect any possible micro surface defects.

ALTA manufactures customized chromed piston tubes and telescopic cylinders.

ALTA manufactures customized chromed piston tubes and telescopic cylinders.